Views: 0 Author: Light M&E Publish Time: 2025-04-12 Origin: Site

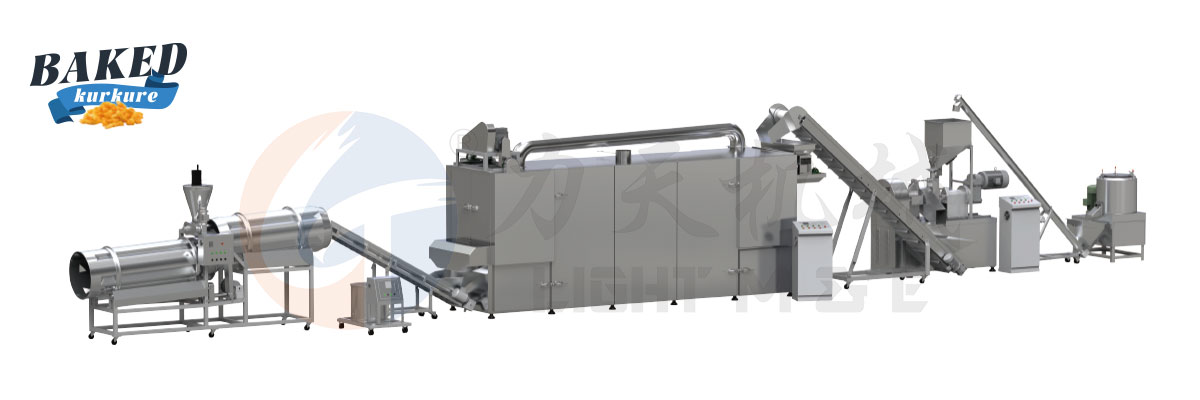

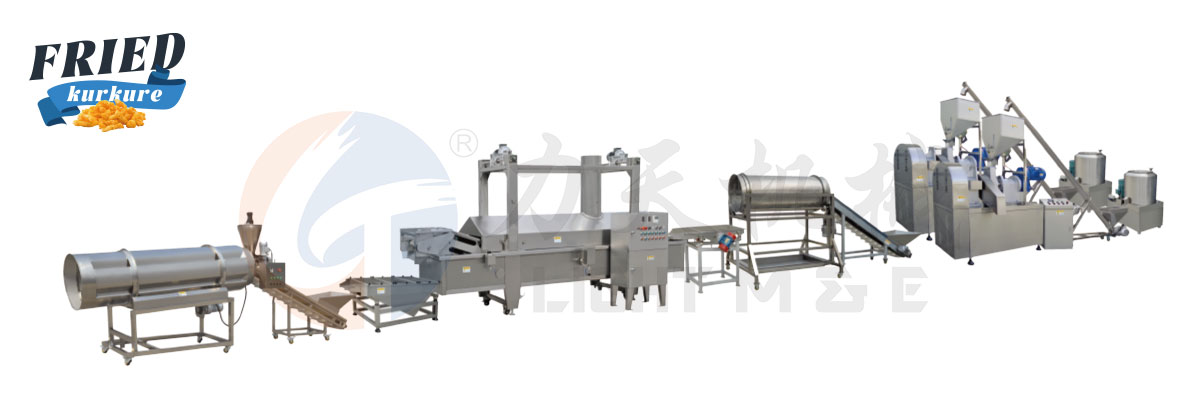

Kurkure, Cheetos, NikNak and corn cobs are the world's best-selling puffed snacks. The core of their industrial production lies in efficient and stable extrusion technology. The extrusion production line launched by Shandong Light Industry Electromechanical Co., Ltd. is specially designed to meet the large-scale production needs of such products. It has both flexibility and intelligent control to help customers quickly occupy the market.

Extrusion puffed snack production line technology

1. Extruder core process

• Efficient extrusion: Adopt intelligent temperature control system to ensure that the raw materials are evenly puffed under high temperature and high pressure,

2. Scientific proportion of raw materials

• Diverse formulas: traditional raw materials such as corn flour, wheat flour, potato starch, etc. Pea flour, quinoa and other healthy raw materials can be added to adapt to consumer preferences in different regions.

3. Extrusion molding

• Multiple mold selection: Quickly change the mold system to produce various forms such as tubular, spiral, and spherical. Supports complex mold forming such as Kurkure's curled shape and Cheetos' strip structure

• Bake (healthy) or fry (crispier) the formed product until golden.

5. Seasoning and packaging

• The seasoning machine evenly coats the flour, supports a variety of flavors, and seals and packages after cooling.

Notes

1. The raw material mixing ratio must be accurate to ensure consistent product texture.

2. The extruder temperature and pressure need to be adjusted according to product characteristics.

3. Pay attention to time control when baking or frying to avoid overheating.

Applicable scenarios

• Food factory upgrade - improve existing production capacity and product diversity

• Entrepreneurial project landing - provide mature solutions for emerging snack brands

• R&D innovation - realize the testing of puffed products with different raw materials and shapes

Why choose our extruder production line?.

• Intelligent control - PLC touch screen monitors temperature, pressure and other parameters in real time to reduce human errors.

•After-sales guarantee – providing full-cycle services including formula debugging, operator training, and annual maintenance.

Get the solution now

If you need a customized production line or get Kurkure's complete production process manual, please contact us!