Views: 0 Author: Site Editor Publish Time: 2026-01-08 Origin: Site

Against the backdrop of rapid growth in the plant-based food market, textured plant protein (TVP), as an important raw material for plant-based meat products, has made its production process and equipment selection a key focus of the industry. Shandong LIGHT M&E CO.,LTD.drawing on years of experience in protein extrusion and puffing equipment projects, provides a brief analysis of the key points for configuring a textured plant protein production line .

With the continued rise in demand for plant-based meat and vegetarian meat products, the application of textured protein, made from soy protein and pea protein , is constantly expanding. Textured plant protein (TVP) is widely used in products such as vegetarian meat chunks, vegetarian meat granules, and plant-based meat fillings due to its good fiber structure, chewiness, and rehydration properties.

From a production process perspective, twin-screw extrusion puffing technology is the core method for realizing the fibrous molding of plant proteins. Therefore, a stable and reliable tissue protein production line cannot be separated from a high-performance twin-screw extrusion puffing machine .

In the production of textured proteins, the twin-screw extruder not only performs the shaping function but is also a key piece of equipment determining the product's texture, primarily in the following aspects:

Protein Structure Reorganization and Fibrosis

During extrusion, plant proteins undergo high temperature, high pressure, and strong shearing, causing protein molecules to align in a specific direction, forming a porous, fibrous structure.

Key process parameters are controllable.

The stringiness, density, and rehydration properties of textured proteins depend on temperature zoning, moisture control, and screw shear strength during extrusion.

Compatible with a variety of protein raw materials

Through reasonable screw combination and parameter adjustment, it can meet the production needs of different formulations such as soy protein, pea protein, and wheat protein.

Stable equipment performance and precise process control are the foundation for ensuring the consistency of tissue protein products.

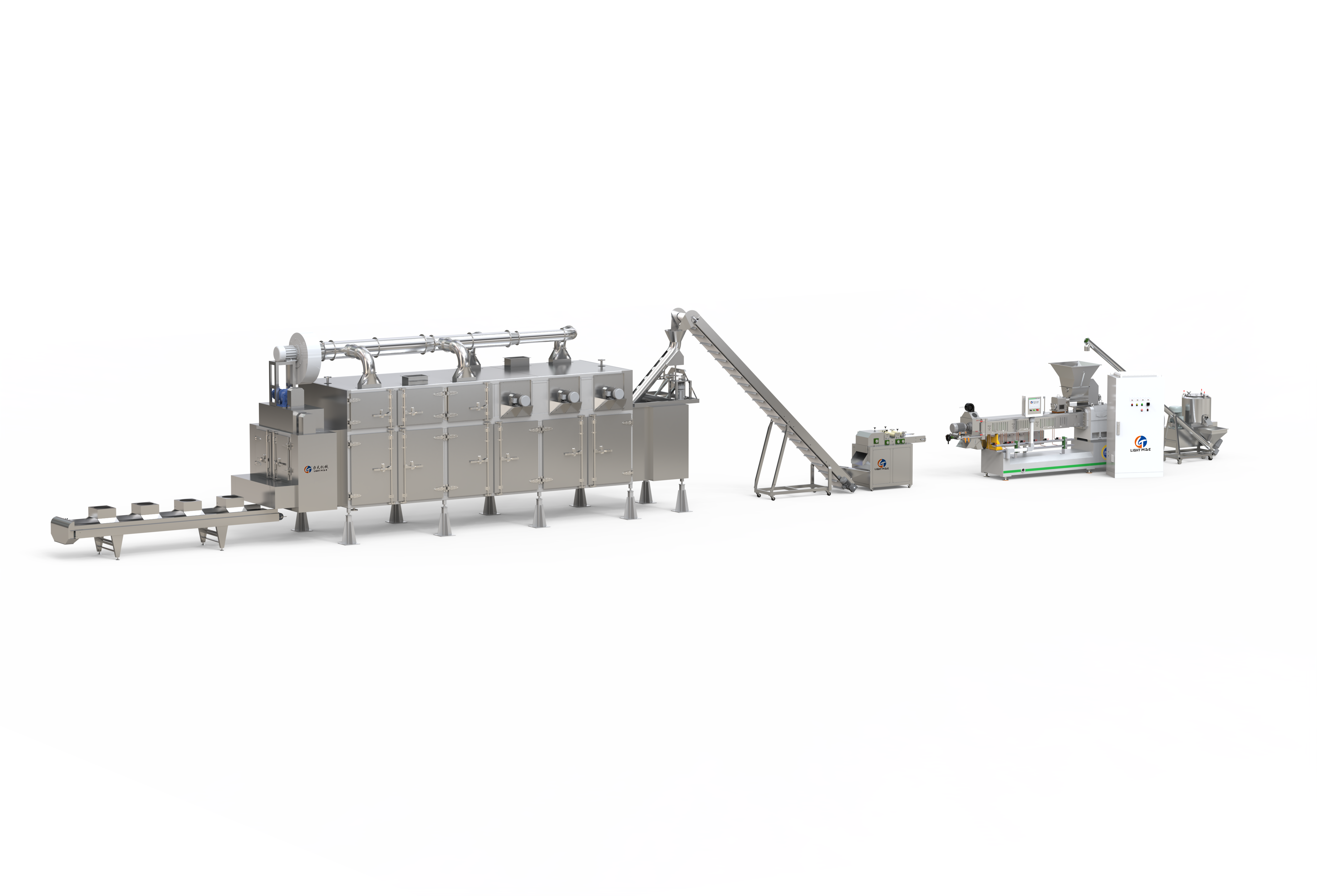

A complete tissue protein production line typically consists of the following core systems:

The raw material pretreatment and batching system

enables precise metering and uniform mixing of protein powder, water, and excipients, providing stable raw materials for extrusion puffing.

The core section of extrusion puffing

is based on a twin-screw extruder , and is equipped with a feeding system, a liquid addition system, and a die head device, which determines the basic structure of the protein.

The drying and post-processing system

cuts, dries, and cools the extruded protein tissue, reducing moisture and stabilizing the fiber structure, thereby improving storage and rehydration properties.

Proper matching between different work sections helps improve the stability and continuous production capacity of the entire production line.

When planning equipment for a tissue protein production line , it is recommended to focus on whether the equipment supplier possesses the following capabilities:

Mature experience in tissue protein extrusion puffing process

Complete production line system integration capabilities

Process solutions for different products (TVP, high-moisture texture protein)

Continuous technical support and equipment stability assurance

Shandong LIGHT M&E CO.,LTD.specializes in food extrusion and puffing equipment and overall solutions for textured protein production lines , and can provide system support from equipment selection to process planning according to customer needs.

Building a tissue protein production line is a systematic project. Stable and efficient tissue protein production can only be achieved by fully understanding twin-screw extrusion puffing technology , rationally configuring core equipment, and optimizing the overall process flow.

If you are planning a plant-based meat or textured protein production project , please contact Shandong LIGHT M&E CO.,LTD. to obtain more targeted equipment and process solutions.