Views: 0 Author: Site Editor Publish Time: 2026-01-15 Origin: Site

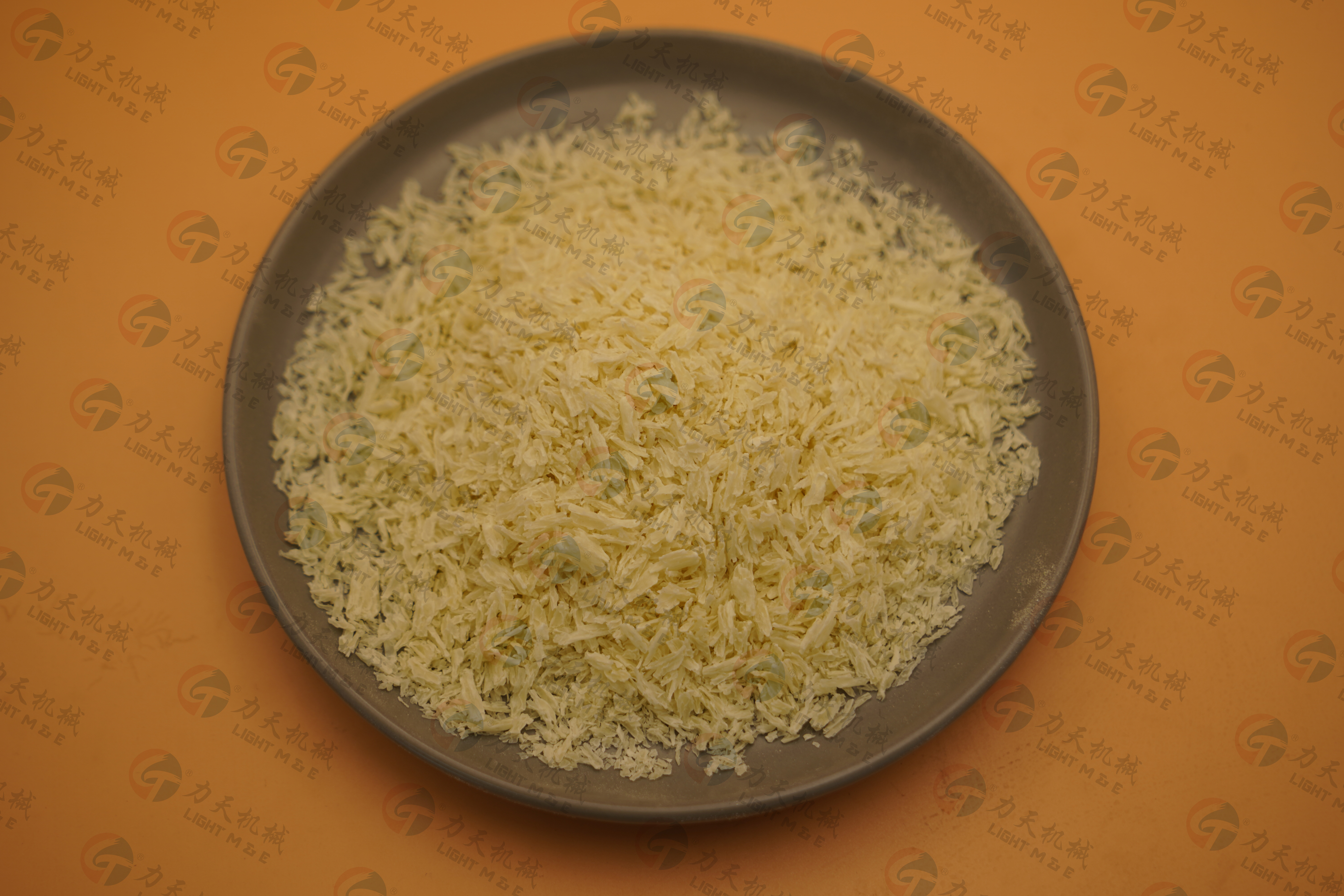

As market requirements for fried food coatings continue to rise, breadcrumbs are no longer evaluated solely on basic functionality. Particle uniformity, crisp texture, coating adhesion, and oil absorption control have become key indicators of product competitiveness. Against this background, the extruded breadcrumb production line, centered on a twin screw extruder, is increasingly recognized as an efficient and stable manufacturing solution.

Traditional breadcrumbs are typically produced from baked bread that is dried and crushed, a process characterized by long production cycles, high energy consumption, and limited consistency in particle size and texture. In contrast, modern puffed breadcrumb processing lines utilize extrusion puffing technology to directly form porous structures, resulting in lighter texture, improved crispness, and more uniform coating performance.

In an industrial breadcrumb production line, the twin screw extruder plays a critical role in material shaping and structural control. By adjusting formulation parameters, screw configuration, and die design, manufacturers can produce extruded puffed breadcrumbs in various particle sizes and shapes to meet different application needs, including panko-style breadcrumbs and specialized coatings for fried foods. The continuous extrusion process also ensures stable color, density, and quality from batch to batch.

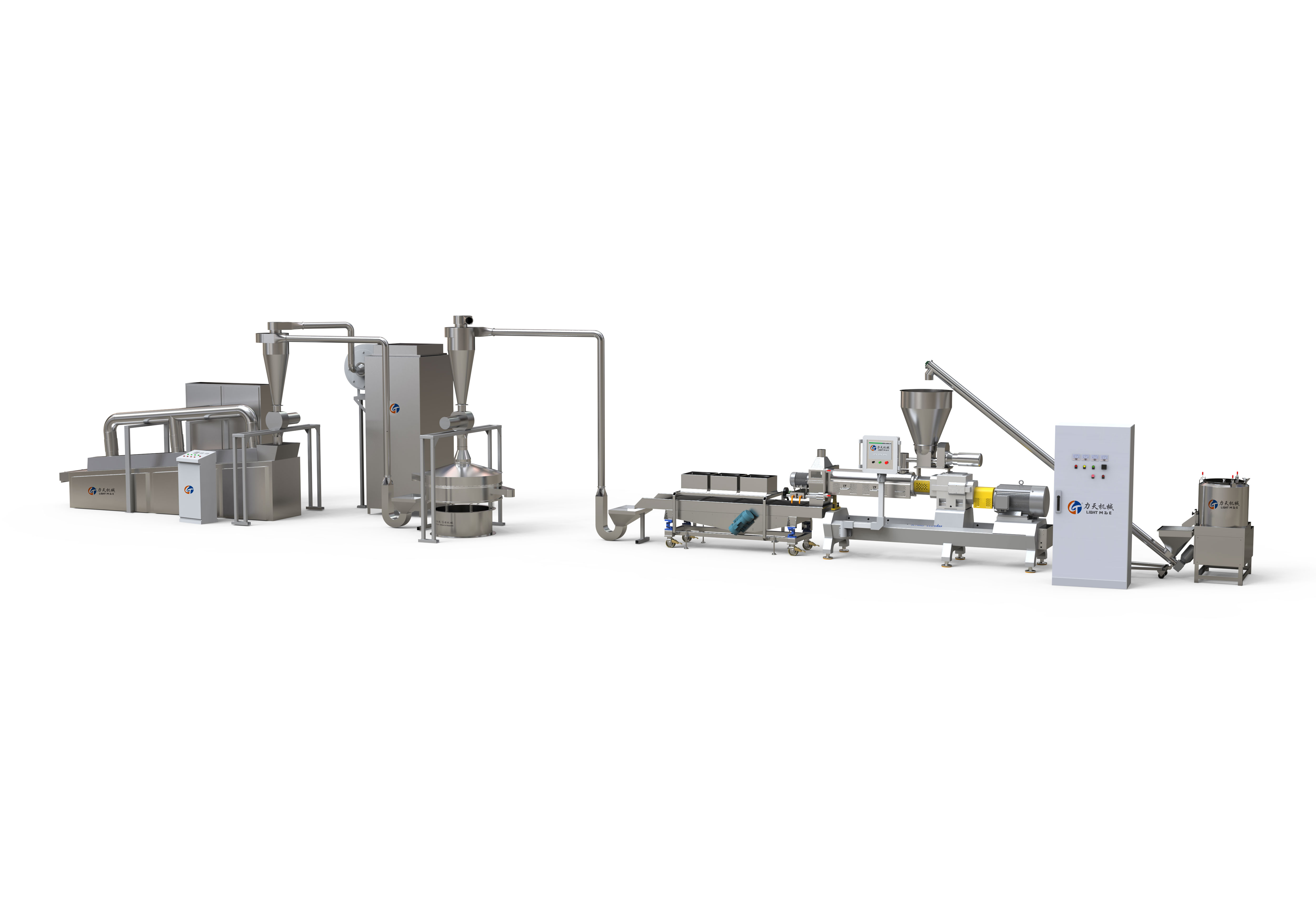

A complete breadcrumb extrusion line typically consists of raw material mixing, twin screw extrusion and cutting, primary drying, crushing and grading, final drying, and cooling. Through rational equipment configuration and precise moisture control, the production line can achieve large-scale, continuous operation while maintaining low oil absorption and consistent product quality.

With its flexibility, automation level, and cost-efficiency, the twin screw extruder for breadcrumbs provides food manufacturers with a reliable path to upgrade traditional processes and respond quickly to changing market demands. As a result, extruded breadcrumb manufacturing is becoming a preferred solution for companies seeking higher-quality coatings and sustainable production efficiency.With its flexibility, automation level, and cost-efficiency, the twin screw extruder for breadcrumbs provides food manufacturers with a reliable path to upgrade traditional processes and respond quickly to changing market demands. As a result, extruded breadcrumb manufacturing is becoming a preferred solution for companies seeking higher-quality coatings and sustainable production efficiency.