Views: 0 Author: Site Editor Publish Time: 2025-12-31 Origin: Site

With the continued growth of the pet economy, niche markets such as dog food, cat food, and exotic pet food are developing rapidly. In various pet food production lines, the twin-screw extruder remains an indispensable core piece of equipment. This article will briefly explain its role in pet food production and provide a reference for equipment selection.

Twin-screw extrusion puffing is not only used for molding, but also directly affects product quality and function:

To improve nutrient absorption,

the raw materials are fully cooked under high temperature and pressure, resulting in starch gelatinization and protein denaturation, which effectively improves digestibility and reduces microbial risks.

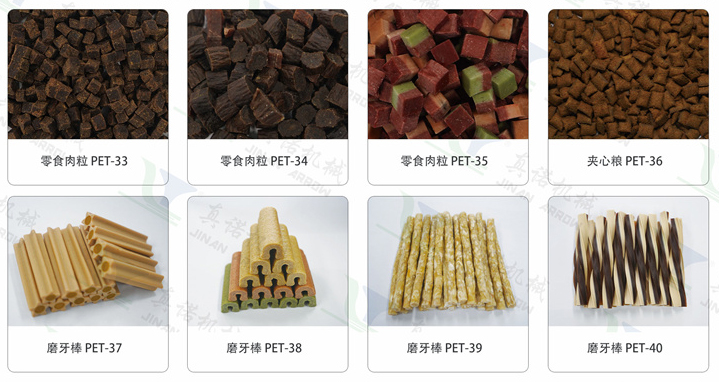

Flexible molding to meet diverse needs:

By changing the mold, pellets of various shapes and densities can be produced to suit different pet stages and product positioning.

It supports the production of functional pet food,

enabling stable production of extruded dry food, floating aquatic feed, and hollow pellets, facilitating subsequent spraying of oils and palatability enhancers to improve palatability.

It can be said that the performance of the extruder directly determines the stability, diversity, and market competitiveness of pet food.

When selecting equipment, it is recommended to focus on the following aspects:

Whether the raw material adaptability can stably handle formulas with high meat content, high oil content, and high moisture content; whether the screw and die head support quick replacement to facilitate product upgrades.

2. Does the process control stability

include multi-stage independent temperature control and a stable transmission system? Is the operating system intuitive and easy to store formulas and switch products?

3. Whether the production capacity and durability

of the equipment meet the current output and leave a margin; whether key components such as screws and barrels are made of wear-resistant and corrosion-resistant materials to reduce long-term maintenance costs.

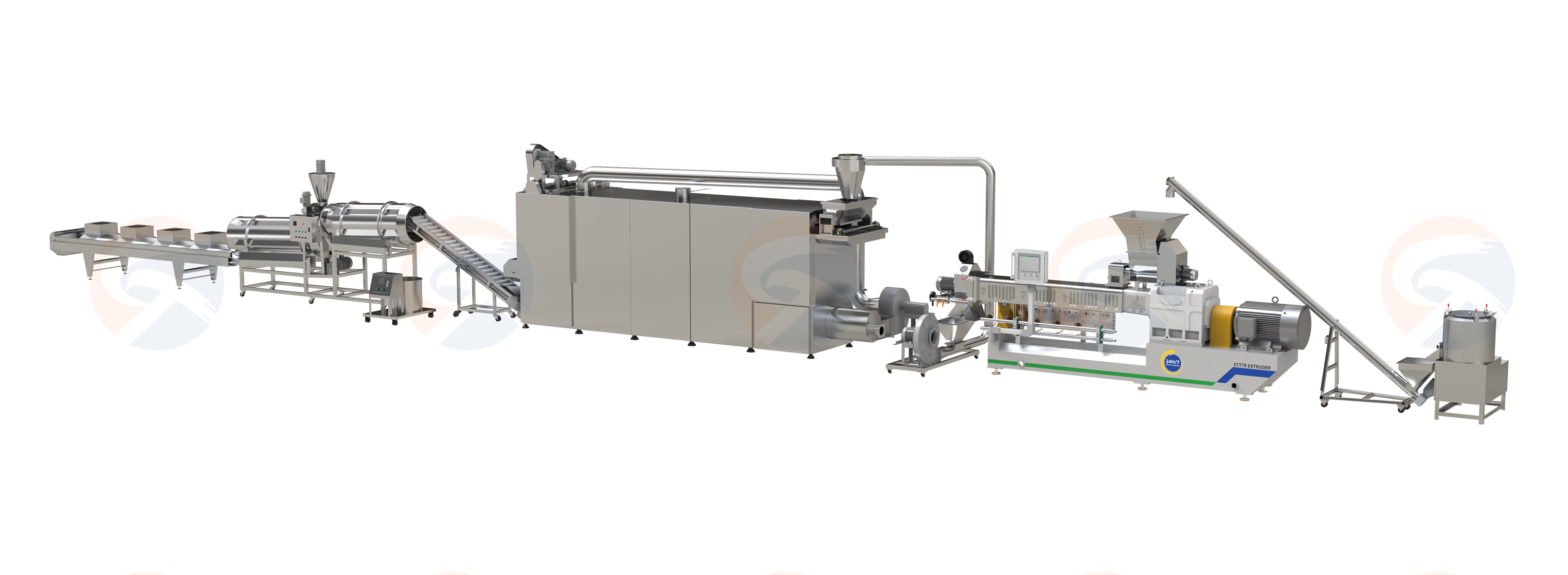

Twin-screw extruders need to work efficiently with the entire production line:

The front-end connects to the ingredient batching and mixing system to ensure stable and uniform raw material distribution.

The back-end interfaces with drying, cooling, spraying, and packaging equipment to ensure matching capacity and smooth processes.

A well-designed production line can effectively avoid production bottlenecks and improve overall efficiency.

Summarize

Extruders are a key investment in pet food production, and their selection should not be based solely on price, but should comprehensively consider equipment performance, process compatibility, and long-term operational value.

Shandong LIGHT M&E CO.,LTD not only provides stable and reliable twin-screw extruders, but also offers customized complete production line solutions to meet different needs such as high-meat pellets, grain-free pellets, and functional pet foods, helping customers achieve efficient and stable production.

If you are planning or upgrading your pet food project, please feel free to contact us. We will provide you with more targeted equipment and process suggestions.