Views: 0 Author: Site Editor Publish Time: 2025-12-27 Origin: Site

With the growing demand for healthy breakfasts, breakfast cereal corn chips have become an important category of puffed cereal foods due to their crispy texture, rich nutrition, and convenient consumption. The stability of corn chip product quality largely depends on the process design of the production line and the selection of core equipment.Shandong LIGHT M&E CO.,LTD , drawing on years of experience in cereal puffing equipment, has launched a comprehensive solution for efficient and stable breakfast cereal corn chip production lines.

High-quality corn chips should have characteristics such as uniform puffing, regular shape, crisp texture, and natural flavor. In actual production, common challenges mainly include:

Uneven puffing degree affects the consistency of taste.

Nutrient loss during high-temperature processing

Insufficient stability in molding and drying during continuous production

Therefore, higher requirements are placed on the level of automation and process control capabilities of the production line.

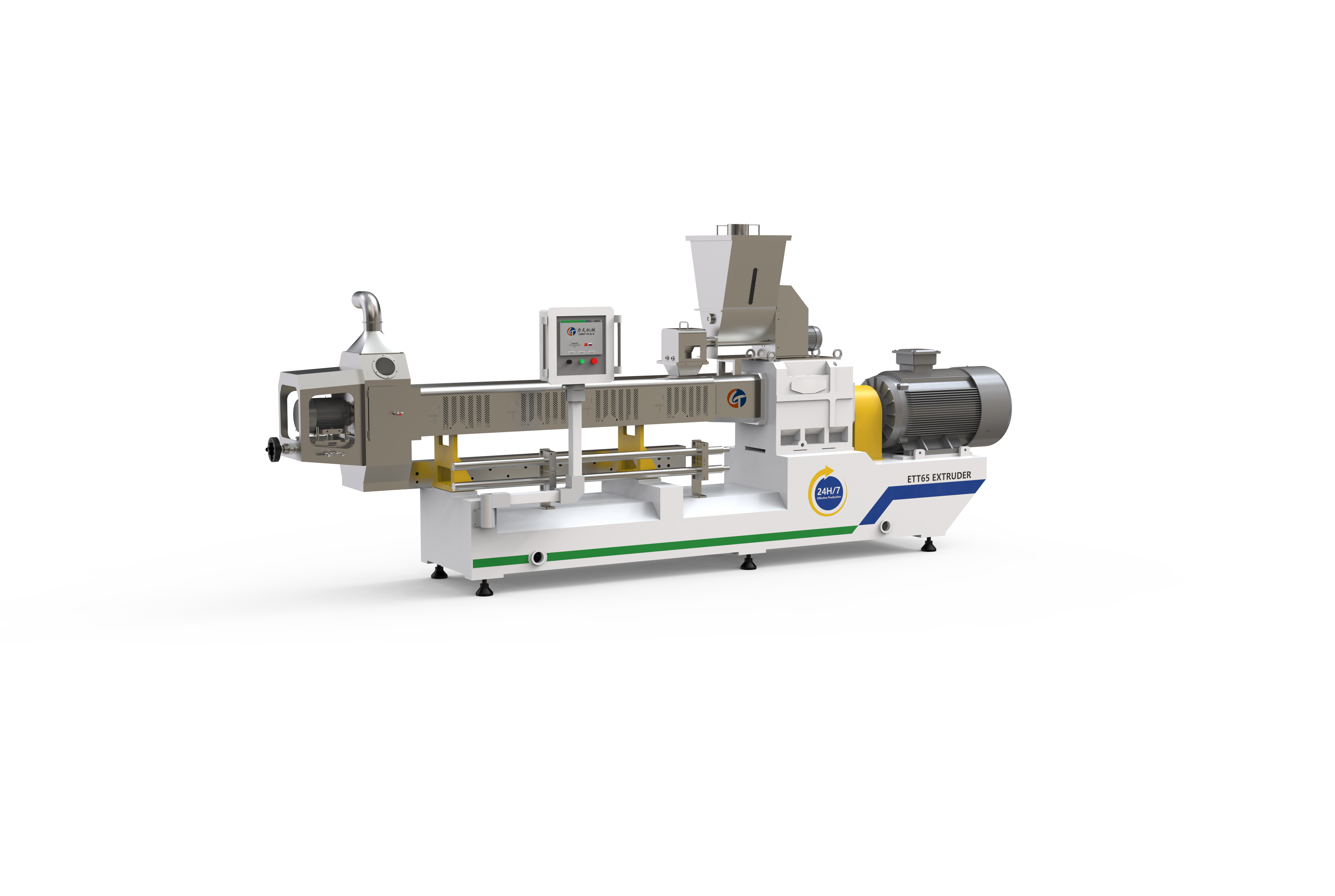

Breakfast cereal corn flake production lines typically use a twin-screw extruder as the core equipment. This equipment integrates processes such as raw material mixing, cooking, extrusion, and shaping into one unit, achieving continuous and efficient production.

By adjusting the screw speed, barrel temperature, moisture content, and mold structure, the puffing structure and thickness of corn flakes can be precisely controlled, resulting in a stable and crispy product texture. Furthermore, the twin-screw extruder is highly adaptable to whole-grain formulations, nutritional fortification, and blends of various grains, meeting diverse product development needs.

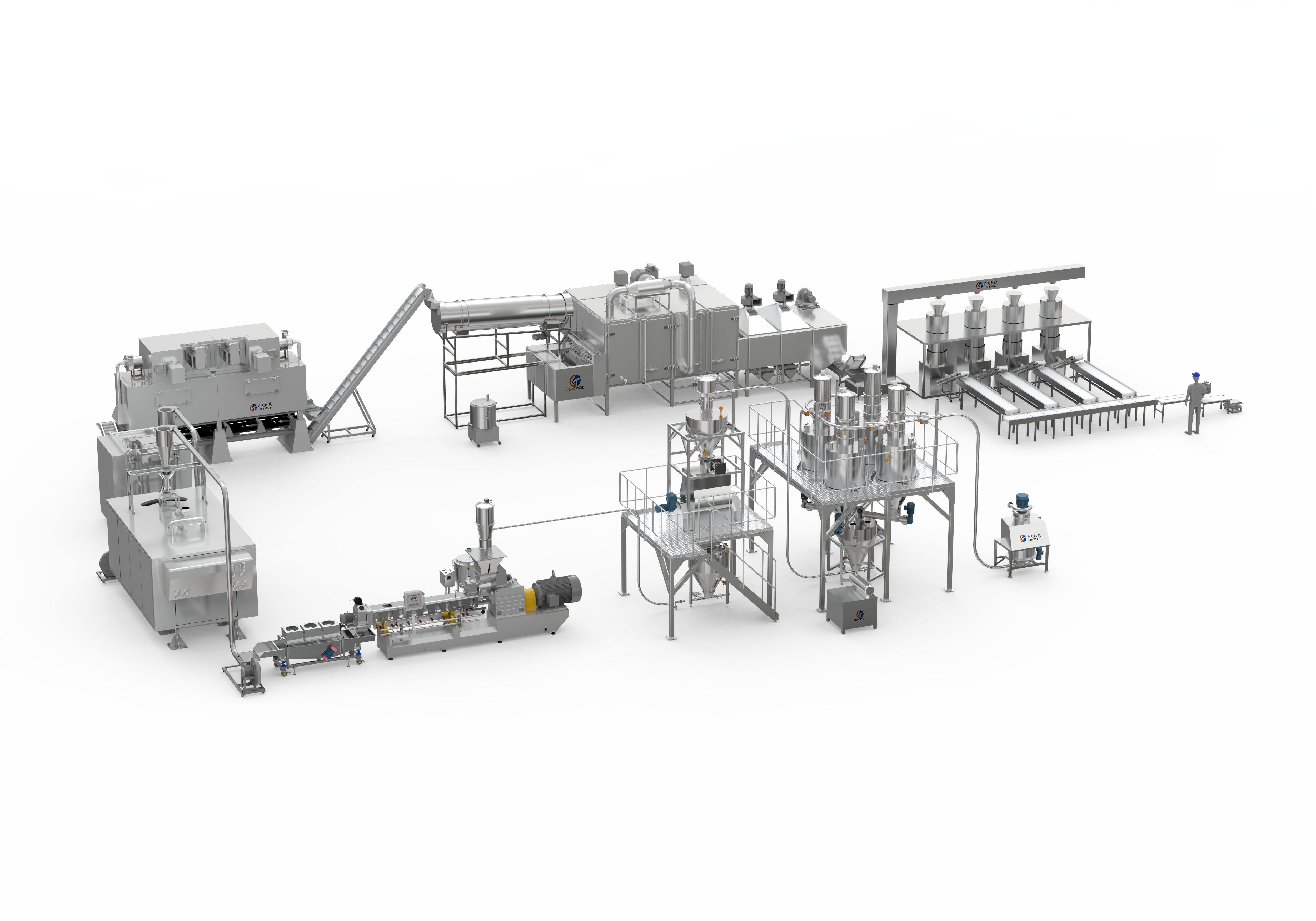

A complete corn chip production line typically includes the following systems:

Raw material pretreatment and mixing system : Enables precise metering and uniform mixing of corn flour and nutritional additives.

Extrusion puffing system : The extrusion and cutting of sheet-like material is completed by a twin-screw extruder.

Drying/Roasting System : Stabilizes moisture removal, resulting in a golden-yellow color and the aroma of roasted grains.

Flavoring, Cooling and Packaging System : Completes the flavoring and automatic metering and packaging of syrups and powders.

Reasonable matching of production capacity at each stage can effectively improve yield and product consistency.

When planning a breakfast cereal corn flake production line, the equipment specifications and automation level should be rationally configured based on the target market and product positioning. At the same time, selecting a puffing equipment manufacturer with capabilities in complete line design, process testing, and after-sales support can effectively reduce project risks and improve the return on investment.

The breakfast cereal corn flake production line, based on twin-screw extrusion puffing technology, is a mature solution for achieving large-scale, standardized production. Jinan Zhennuo Machinery provides customers with one-stop services, from equipment selection and process design to complete line delivery.

If you need information on the price, equipment configuration, or technical solutions for breakfast cereal corn flake production lines , please contact Shandong LIGHT M&E CO.,LTD for professional support.